In order to support the country’s major strategic and major engineering research and development, the Ministry of Finance, together with the Ministry of Science and Technology, the National Development and Reform Commission, the General Administration of Customs, and the State Administration of Taxation, issued a “Circular on Major Import and Export Tax Policies for Science and Technology†recently, and decided that since 2010, From July 15th onwards, the key equipment and parts that can not be produced domestically for the enterprises that undertake the “National Long-Term Scientific and Technological Development Plan Outline (2006-2020)†Zhongmin Science and Technology Major Special Projects Raw materials are exempted from import duties and import value-added tax.

According to the notice, in addition to companies undertaking projects, they also include universities, research institutes and other institutions.

The major projects of Minkou Science and Technology are high-tech industries, including core electronic devices, high-end general-purpose chips and basic software products, VLSI manufacturing equipment and complete sets of processes, a new generation of broadband wireless mobile communication networks, and high-end CNC machine tools and foundations. Manufacturing equipment, large-scale oil and gas fields and CBM development, large-scale advanced pressurized water reactors and high-temperature gas-cooled reactor nuclear power plants, water pollution control and treatment, cultivation of new varieties of genetically modified organisms, creation of major new drugs, and prevention of major infectious diseases such as AIDS and viral hepatitis.

Non Woven Fabric

FY-hengfa nonwoven Fabric series: PET Polyester Spunbond Non woven, Meltblown Nonwoven, Activated Carbon Nonwoven Fabric, Nonwoven Filter Bag,Nonwoven Fabric For Auto Filter.

Such as:

100% PET/PP spunbond nonwoven fabric.

It is similar to filament yarn production. From the chips storage, the polymer is vacuum-fed to a dosing station on top of the extruder. Inside the extruder, it becomes melted and homogenized. Passing a filter system and a spin pump, the melt is fed into the spin beam or spinnerets, which form a curtain of filaments. The filaments are cooled by means of a stream of air in a blowing area, drawn by aerodynamic forces and then transported to the downstream discharge channel. For nonwovens, instead of a further stretching process for filament yarns, the filaments are swirled around and then deposited on the wire mesh belt as a random nonwoven. This web is transferred to a bonding calender that uses heat and pressure to set such physical properties as tensile strength and elongation of the final product. After cooling, the material can be wound.

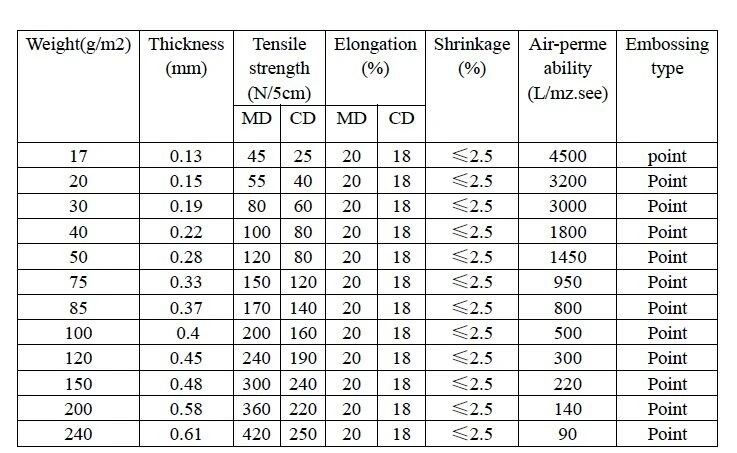

Product :Spun-bonded Nonwoven

Material :100% polyester

Width :0.15-3.20m.

Specification:1000M-4500M/roll or customized

Weight :10gsm-260gsm

Use :

1. Medical : face mask ,surgical cloth ,bedsheet ,disposable cap , shoose cover .

2. Packing : shopping bag , tablecloth ,wallpaper ,compund packing material .

3. home textile : pillow case ,mattress cover ,linling .

4. Industry : protect the crop from insect .cold weather .filtration materials

Non Woven Fabric,Pet Non Woven Fabric,Activated Carbon Nonwoven Fabric

Hebei Fangyu Trade Co., Ltd. , https://www.laderytrading.com